EPOXY QUICK FIND LINKS - COMPREHENSIVE

EPOXY RESOURCE WEB SITES - CLICK HERE

Rot Repair

------------------------------------------------------------

Wood Window sill rot repair

Epoxy System Rot Repair

site co-sponsors:

OUR FAVORITE ONLINE EPOXY VENDOR SITES

Top two epoxy vendor sites on the Internet - #1 (huffnpuff.us) and #2 (epoxyproducts.com)

MOBILE FRIENDLY everything-epoxy web site (with links back to "full screen" web sites) CLICK HERE

"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful.

Quality people backing a quality product is the only way to go!" Joe

"After 17 years there is still no reason to buy from anyone else, great product, and great prices and the boats are still looking good." J.F.- 2-2-17

Search the EPOXY-ONLY World Wide Web search engine

for your Epoxy Related Search term

CLICK HERE FOR EPOXY RELATED WEB SEARCHES

Getting Started

terms and concepts you need to know up front

Rot (wet rot)

Most of the rot we deal with is associated with water. The rotten wood is damp or wet with water. Their is no magic epoxy or product that will drive the water out and not epoxy product that will in some magic way replace the water. The wood will remain wet and continue to rot while the epoxy forms a hard crust in places that it pools and collects, mostly on the surface. You certainly want to remove all of the wet rot or as much as you can. You want to use epoxy products that will bond to wet or damp surfaces. Only a handful of epoxies will do this, most need completely dry surfaces. It is always best to dry out the wood completely but this is rarely possible (especially when it is the core material in an encased boat deck). Most how-to videos want you to remove all of the rotten wood. Removing all the rot is, once again, always the best way to go.

Rot (dry rot)

Dry rot is like dry sawdust. When vendors are show how well their products 'penetrate' the wood or the rot, they always use end grain balsa wood or dry rot. Of course any liquid will soak in or penetrate under those conditions. Dry rot is pretty rare.

Penetrating Epoxy

99% of penetrating epoxies (also used for sealing and as a primer for other products) are just solvent thinned epoxy. The solvents soak in and carry the epoxy with it. The solvents then mostly evaporate away (not all of it) leaving the epoxy behind. As mentioned above, these products will not drive the water out of the rotten wood and in many cases will not bond to the damp surface. Most epoxies do not contain solvents. Some of these no solvent epoxies are sort of watery (but still nearly not as thin as water). Gravity will let these epoxies get into voids and cracks (unless trapped by air bubbles etc.). Instead of purchasing a solvent thinned epoxy (which you cannot buy in California) you can add solvent to a solvent thinned epoxy to help thin it and help it penetrate. Note - do not use solvent thinned epoxies in confined spaces as the solvents have no way to evaporate into the air.

Repairing rot - website

Epoxy System Rot Repair

Table Of Contents

(read about these below)

*** How-to Videos

*** Rot repair example 1 (on wood trim etc.)

*** Rot repair example 2 (wood core in fiberglass boat deck)

*** Rot repair example 3 (log cabin home rot repair)

*** Killing / treating rot with anti-freeze

*** Product reviews and purchasing information for products mentioned on this web site (low V epoxy, ESP 155 epoxy, Wet Dry 700 epoxy paste) - CLICK HERE - THESE EPOXIES ALL BOND TO WET OR DAMP SURFACES

*** More help and information

| Low V epoxy - CLICK HERE for data/tech documents in PDF format. This link, and links for all products, can also be found at epoxyproducts.com/datamsds.html |

HOW-TO ROT REPAIR VIDEOS

1) some of the best How-To rot repair videos are produced by "THIS OLD HOUSE" TV show

2) Google THIS OLD HOUSE ROT REPAIR

3) NOTE: use the ESP 155 epoxy or Low V epoxy as the bonding - sealing - primer mentioned in the THIS OLD HOUSE videos. Wet Dry 700 epoxy is a kevlar (tm) re-inforced epoxy (comes in plastic containers, not available in caulking tubes)

Also visit our ESP 155 primer/sealer page at : everything-epoxy.info

product reviews and purchasing information for products mentioned on this web site (low V epoxy, ESP 155 epoxy, Wet Dry 700 epoxy paste) - CLICK HERE

Rot repair example 1 (on wood trim etc.)

In A Nutshell - rot repair1) remove the worst of the rotten wood2) saturate the wood with a thin epoxy (Solvent free Low V or solvent thinned ESP 155)3) fill in the void space with thick epoxy, (Wet Dry 700) blocks of wood, foam, putty etc. Some people will add sand to the epoxy (horizontal repairs) or insert pieces of steel rebar or metal for strength.4) sand smooth5) seal the sanded top surface with more Low V epoxy or ESP 155 epoxy6) paint the surface (usually latex paint to match the surround areas).

|

wood spar - rot removed

wood spar - getting ready to replace

removed rotten wood with Wet Dry 700

epoxy paste

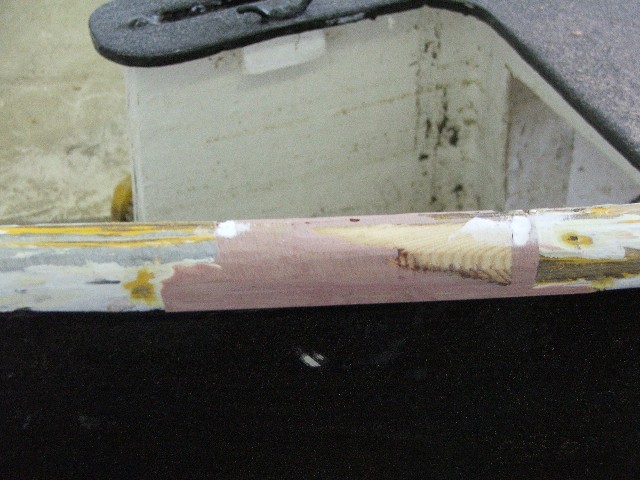

boat rail rot repair - pink is the epoxy filling in the void from the removed rotten wood

Rot repair example 2 (wood core in fiberglass boat deck)

|

Spongy (rot) Boat Deck Core an entirely different problem

|

| "I used your low-v epoxy to reattach my deck to

it's core deck this year. A lot of the products on the market for

"flooding" a delaminated deck use watery-thin epoxy that is full of

thinners. They cure up gummy, or brittle, they shrink, and they seep

away from voids rather than filling them in. That low-v is thin enough

to flow _everywhere_ without the burden of all those thinners.

My strategy involved small hole-saw holes in a 1-foot polka-dot pattern, large enough to fit a crow-bar to lift up the top laminate a little, and then an array of smaller holes to make sure I had complete coverage. I'd lift a little laminate with the crow bar, pour in the low-v, and after a few minutes it would start pouring out of all the lower holes. I set weights down on the deck to squish it all together tightly after I was content that the entire area had been flooded. It was amazing the little holes that the Low-V would find and start dripping out of from below. I had to be very careful staging my drip-collection in the cabin as a result. The Low V epoxy is thin enough to flow everywhere, but thick enough to hold a nice film in place to bridge any high spots my weights hadn't eliminated. And no thinners to trap inside the deck. You've got to start marketing this stuff directly for "flooding" delaminated decks! My decks went from spongy soft to rock solid." Satisfied Customer 4/16

|

| Low V epoxy is solvent free, thin and bonds to wet or damp surfaces. Popular for all sorts of ROT repair and for sealing the floors (from chemicals) on Shipping Container sold to the public. |

| Low V epoxy - CLICK HERE for data/tech documents in PDF format. This link, and links for all products, can also be found at epoxyproducts.com/datamsds.html |

Rot repair example 3 (log cabin home rot repair)

|

|

|

--

CUSTOMER FEEDBACK:

"Hello: I would be glad to help

someone else work through this

seemingly daunting task.

I think what really helped me was to realize that this entailed a lot of very doable individual tasks , all within the skill level of most handymen or women. One other note: patience is required. Step 1/ remove all rotted wood. In our case , this was about 1/2 the diameter of our 12" logs. I found the best tool to remove the rotted wood was a 12"or 14" electric light duty chain saw. Step 2/ Then I sprayed anti-freeze on the remaining wood to stop the rot. I let the logs dry for several days and then repeated the anti-freeze spraying. Again, I let it completely dry for several days. Step 3/ I soaked the remaining logs with Low V 2-part epoxy ,let it dry for a couple of days and repeated the process. I used a paint brush to apply the Low-V , and generously applied it. Use a throw-away paint brush each time , because it will be unusable after use. Step 4 / I then cut dimensional lumber to replace the rotted wood . I used 2" x ? ,because they were cheap and convenient to work. I would cut each one to fit individually . So the first one was a 2" x 12" , set vertically. Then the next board was a 2" x 8" , then a 2" x 6" , and ultimately a 2" x 4". Then I sandwiched them all together , and deeply counter-sunk the screws so I wouldn't interfere with my rounding off the exterior of the wood. This may sound confusing , so let me describe what the end result looked like. Envision a 12" log 3' long. Half of this log was rotted and removed. So my sandwich to replace the rotted wood was a 2" x 12" , 3' long , a 2" x 8" 3' long , a 2" x 6" 3' long and a 2" x 4" 3' long. These would all be set vertically and attached together with a couple of long screws [ or you could glue them, I would think]. Before you attach them together you can remove the excess material with a circular saw , a band saw or your chain saw. The end result is a sandwich of lumber about 6" wide and 3' long , with the outside diameter being a 12" radius to match the 1/2 log remaining. Then I screwed this sandwich to the remaining log [ I used screws made by Fasten-Master Timber Lok. These are not cheap but are very high quality]. Step5/ I mixed a batch of Wet/Dry 700 Epoxy and slathered it over the sandwich and between the sandwich and the remaining original log. If it suits you to thicken this material , you can use sawdust or sand . I found the sawdust thickener to be more user friendly to the last step of removing any wood that doesn't look like a log. The sand is really hard on whatever tool you use to dress up your log. I found the best tool to use for the sculpting of you log is a grinding wheel used on an angle grinder.[ It is called "Gallahad" ]. A caution: This is a really aggressive tool and you need to hang on. But you could use any tool you feel comfortable with : Body grinder , chain saw , disc sander or even files. I wish you well. One last word : Paul Oman (owner of Progressive Epoxy - 603 435 7199) is a very knowledgeable man , and freely shares his knowledge. His products are high quality and as represented. And he answers his phone. Ralph" |

Killing / treating rot with anti-freeze

Below is an article written by Dave Carnell - a chemist and scientist and something of an icon in the marine/boating world. I believe the article was written in 2000. Sadly, Dave died in 2011.

Chemotherapy for Rot

Once rot gets a toehold in wood it is difficult to cure completely -- it is like a cancer. Digging out the rotted

wood will still leave spores and water in the sound wood. After you fill in the cavity with something like epoxy,

the rot continues to flourish underneath. Products promoted to make rotted wood sound and stop rot penetrate only

until they meet water, with which they do not mix. Under the solid repair rotting goes on. With one exception (more

later), the commercial products sold to treat dry wood to prevent rot are completely ineffective against established

rot in wet wood because they are dissolved in petroleum solvents and oil and water do not mix.

There are two commonly available inexpensive materials that will kill rot in wood and prevent its recurrence. First,

there are borates (borax-boric acid mixtures) which have an established record in preventing rot in new wood and

in killing rot organisms and wood-destroying insects in infested wood. Second, there is ethylene glycol, most readily

available as auto antifreeze-coolant. Glycol is toxic to the whole spectrum of organisms from staphylococcus bacteria

to mammals. All of the published material on its effectiveness against wood-destroying fungi and insects that I

am aware of is the result of my investigations over the past 15 years.

Both borate solutions and glycol penetrate dry and wet wood well because they are water-soluble; in fact, penetration

by glycol is especially helped by its extreme hygroscopicity -- its strong attraction for water. For both, the

fact that they are water-soluble means they are not permanent solutions to rot in wood that is continually exposed

to water-below the waterline and in ground-where they will eventually be extracted-dissolved out.

I first was interested in glycol as a wood-stabilizing agent, where it is in many ways superior to polyethylene

glycol (PEG), and it was during this work that I realized the useful effect of glycol on organisms, though I was

pretty dense in interpreting the first experiment.

The ladies immerse the stems of greenery such as magnolia branches in glycerin to keep them green. Glycol is very

similar to glycerin in all its physical properties and much cheaper, so I stuck a magnolia branch in antifreeze.

The next day it was brown. After the third attempt I tumbled to the fact that the glycol was killing the greenery.

This was the reason that glycol never replaced glycerin in applications such as a humectant for tobacco and an

ingredient of cosmetics and pharmaceutical ointments, though it had all the desirable physical properties.

I had two 2" thick slabs of a 14" diameter hickory tree that had just been cut. I treated one with antifreeze

and left one untreated. I was looking at wood stabilization, not rot prevention. After about six months stored

inside my shop the untreated control was not only cracked apart, but it was sporting a great fungal growth, while

the treated slab was clean.

The local history museum wanted to exhibit two "turpentine trees", longleaf pines that had many years

ago been gashed to harvest the sap that made everything from turpentine to pine tar. The trees delivered to us

after cutting were infested with various beetles and had some fungal growth. I treated them with antifreeze outside

under a plastic tarpaulin every few days for three weeks. They were then free of insects and fungus and have remained

so after being moved inside and installed in an exhibit over four years ago.

I took three pieces from a rotting dock float that were covered with a heavy growth of fungus, lichens, etc. I

treated one with antifreeze painted on with a brush, the second with a water solution containing 23% borates (as

B2O3), and left the third untreated as a control. They were left exposed outdoors and were rained on the first

night. By the next morning the growth on the antifreeze-treated piece was definitely browning and the borate-treated

piece showed slight browning. After two months exposure to the weather the growth was dead on the antifreeze- and

borate-treated pieces and flourishing on the control.

I have a simple flat-bottomed skiff built of plywood and white pine, which has little

resistance to rot. After ten years some rot developed in one of the frames. It may have begun in the exposed end

grain. It consumed the side frame, part of the bottom frame, and part of a seat brace fastened to the side frame.

The plywood gusset joining the side frame to the bottom frame was not attacked. I excised the rotted wood, saturated

all with ethylene glycol antifreeze to kill all the rot organisms, and there has been no further deterioration

in four more years afloat with wet bilges. I have not replaced any pieces, as I am building another boat that can

replace it; that is more fun, anyway.

I have a 60+-year old case of the fungus infection known as "athlete's foot". Many years ago it infected

the toenails extensively. The whole thing was pretty grotesque. My dermatologist and druggist both assured me there

is no known cure. About six years ago I started using antifreeze applied under the nails with a medicine dropper

about every five days. The professionals are technically right. I have not completely cured it, but the nails have

grown out pink and thinned almost to the ends and I never have any trouble with blistering, peeling, or itching

between the toes as I had had for six decades. No drug company is going to have any interest in this because the

information has been in the public domain for so long that there is no opportunity for any proprietary advantage.

The various wood-rotting organisms cannot be anywhere near as tough.

There are two types of borate products commercially available for treating wood-solid sodium octaborate for making

solutions in water (Tim-Bor® and Ship-Bor®) and a 40% solution of sodium octaborate in ethylene glycol

(Boracare®). Their equivalents and more concentrated solutions can be easily prepared from borax, boric acid,

and antifreeze at much lower cost. Keith Lawrence, editor of Boatbuilder offered to sell me advertising if I wanted

to go in the business, but I might run afoul of patents (preparation for individual use is not prohibited), I would

have to get EPA registration, and I could not deliver products anywhere near as cheaply as they can be made from

raw materials available at your supermarket, drugstore, and discount store.

Glycol by itself has one big advantage over solutions of borates in either water or glycol. Glycol penetrates rapidly

through all paint, varnish, and oil finishes (except epoxy and polyurethanes) without lifting or damaging those

finishes in any way. You can treat all of the wood of your boat without removing any finish. The dyes in glycol

antifreeze are so weak that they do not discolor even white woods. Once bare wood has been treated with glycol

or the borate solutions and become dry to the touch it can be finished or glued. IN THE YEARS SINCE I FIRST WROTE

THIS ARTICLE, MY EXPERIENCE HAS BEEN THAT GLYCOL BY ITSELF IS GENERALLY THE BEST TREATMENT FOR KILLING ROT. Gougeon's

research has shown that borate solutions weaken epoxy joints in the treated wood. If a borate solution leaves white

residues on the surface, it will have to be washed off with water and the surface allowed to dry.

If you decide you need to treat with both glycol and borates, this is my preferred process to treat rot. Once you

find soft wood or other evidence of rot, soak it with antifreeze even if you cannot do anything else at the moment.

Paint it on or spray it on with a coarse spray. Avoid fine mistlike spraying because it increases the likelihood

that you will breathe in unhealthy amounts of glycol. Put it on surfaces well away from the really damaged wood,

too. Use glycol lavishly on the suspect wood, which will readily absorb 10-20% of its weight of antifreeze.

Next dig out wood that is rotted enough to be weak. Add more glycol to wet the exposed wood thoroughly. Then add

the 25% borate solution of the recipe below so long as it will soak in in no more than 2-3 hours. Then fill in

the void with epoxy putty and/or a piece of sound treated wood as required. The reasons I use borates at all are:

1) it is a belt-and-suspenders approach to a virulent attack, and 2) over a long period glycol will evaporate from

the wood; especially, in areas exposed directly to the sun and the high temperatures that result.

If there is any question about water extracting the glycol or the borates, you can

retreat periodically with glycol on any surface, painted or bare, and with borate solutions on bare wood.

Glycol's toxicity to humans is low enough that it has to be deliberately ingested (about a half cup for a 150 lb.

human); many millions of gallons are used annually with few precautions and without incident. It should not be

left where children or pets can get at it, as smaller doses would harm them, and they may be attracted by its reported

sweet taste that I have confirmed by accident. The lethal dose of borates is smaller than of glycol, but the bitter

taste makes accidental consumption less likely.

BORATE WOOD PRESERVATIVES:

COMMERCIAL AND HOME-BREWED

Tim-Bor®: Solid sodium octaborate; dissolves in water to make approx. a 10% solution containing 6.6% borate

(B2O3); about $3/lb. plus shipping.

Ship-Bor®: Same as Tim-Bor®; $19.95/lb. plus $2 shipping.

Bora-Care®: 40% solution of sodium octaborate in ethylene glycol; 27% borate content; $70/gal. plus shipping.

Home-Brew Water Solution of Borates:

All percentages for this recipe and the others here are percentages by weight. Based on U.S. Navy spec. of 60%

borax-40% boric acid (this ratio gives the maximum solubility of borates in water); 65% water, 20 %borax, 15% boric

acid; 15.8% borates; borax costs 54 cents/lb. (supermarket), boric acid costs about $4/lb. in drug stores (sometimes

boric acid roach poison, 99% boric acid, is cheaper in discount stores); equiv. to Tim-Bor® or Ship-Bor®

at 30 cents/lb. To make this solution mix the required quantities and heat until dissolved. The boric acid, in

particular, dissolves slowly. This solution is stable (no crystals) overnight in a refrigerator (40°F.), so

can be used at temperatures at least as low as 40°F.

Home-Brew Glycol Solution of Borates:

This is equivalent to Bora-Care® diluted with an equal volume of glycol to make

it fluid enough to use handily; 50% glycol antifreeze, 28% borax, 22% boric acid. To make a stable solution you

mix the ingredients and heat till boiling gently. Boil off water until a candy thermometer shows 260°F. This

removes most of the water of crystallization in the borax. This solution is stable at 40°F and has a borate

content of 26%. With antifreeze at $6/gal. and borax and boric acid prices as above, this is equivalent to Bora-Care®

at about $15/gal.

Product reviews and purchasing information Link

Epoxy System Rot Repair

Wet Dry 700 epoxy putty (bonds to wet or damp wood)

Product reviews and purchasing information for products mentioned on this web site (low V epoxy, ESP 155 epoxy, Wet Dry 700 epoxy paste) - CLICK HERE

THESE EPOXIES ALL BOND TO WET OR DAMP SURFACES

CLICK HERE FOR EPOXY RELATED WEB SEARCHES

More help and information

|

MORE HELP AND INFORMATION |

|

"The Epoxy Guru" FOR CASE STUDY EXAMPLES AND A PLACE TO ASK QUESTIONS - VISIT THE EPOXY GURU or call 24/7 - 603 435 7199 CLICK HERE FOR EPOXY RELATED WEB SEARCHES

|

Large wood rot repair web site - CLICK HERE

Another (simple) web site dealing with rot - CLICK HERE

Epoxy System Rot Repair

###